So, about these split washers…

You know, for years, I just saw these little springy washer things in my box of bits and bobs. Didn’t give ’em much thought, to be honest. If a bolt needed a washer, I’d grab whatever flat one was handy. Sometimes, I’d see these split ones, also called spring lock washers by some folks, and kinda just toss ’em on if I felt like it, not really understanding their deal.

Then I got this old generator project I was tinkering with. Thing vibrated like crazy, I tell ya. Every time I’d run it for a bit, I’d find a bolt or two starting to work its way loose. Drove me nuts! I’d tighten ’em up, good and proper, or so I thought. Next thing you know, loose again. I was about ready to just use some kind of super glue on the threads, which, trust me, you don’t really wanna do most of the time.

That’s when I really started looking into these split washers. I remembered seeing them used on engines and machinery that shook a lot. My old man used to use them on his lawnmower. So, I figured, what the heck, let’s try ’em systematically on this generator.

So, here’s what I did. I went through my stash and also got a fresh pack of these split washers. My process was pretty straightforward:

- I took off the nuts and bolts that were giving me the most grief, the ones that kept loosening.

- I made sure the surfaces were clean, no old gunk or rust.

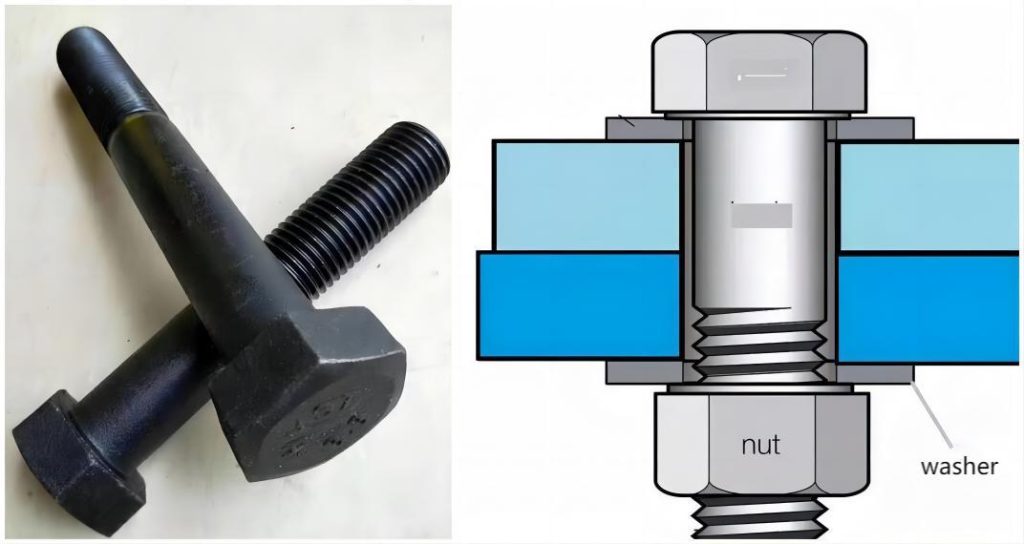

- Then I put one of these split washers under the head of the bolt, or sometimes under the nut, depending on which side was easier to work with or what seemed to make more sense for that spot.

- Then I tightened everything back up. I noticed something right away – when you tighten ’em, you can feel that springiness. It’s like it’s pushing back a little as you get to the final turns. It’s not like a flat washer that just sits there.

And you know what? It made a difference. A real difference. The bolts stayed put a whole lot better. Wasn’t a magic bullet for every single spot, ’cause that generator was a real shaker, but it was a massive improvement. I wasn’t having to re-tighten things nearly as often.

Why they kinda work (or so I figure from using them)

Took me a bit to wrap my head around it, but here’s the simple way I see it. That split in the washer, it makes it act like a spring that’s been kinda coiled up and then sliced. When you tighten the bolt or nut down, you’re squashing that spring, trying to make it flat. It naturally wants to spring back, right? So, it’s constantly exerting a force, pushing against the bolt head (or nut) and the surface it’s tightened against.

This does a couple of things, as far as I can tell from my practical use:

- It creates more friction. That constant spring pressure helps keep the nut from just spinning loose easily when things start to vibrate. It’s like adding extra grab.

- The edges of the split, where it’s cut, can also kinda dig in a tiny bit to the underside of the nut and the surface it’s on. Not like it’s gonna chew up the metal badly, but just enough to add a bit more resistance to loosening, especially when things are vibrating back and forth.

Now, I’ve heard some folks, maybe more on the engineering side of things, say they ain’t all that great for super critical, high-load applications, and there’s fancier locking methods out there. And maybe they’re right, for stuff on airplanes or whatever. But for your everyday machine, your small engines, things around the workshop, stuff that rattles around? I’ve found they do help. They’re cheap, they’re simple to use, and they often do the job of preventing annoying loosening.

One thing I learned, though, and it’s important: don’t over-tighten them to the point where they’re completely flat and have lost all their springiness. If you squash ’em totally flat, they’re not much better than a plain flat washer at that point; you’ve killed the spring action. You want that spring action working for you. And also, on really soft materials, like some soft plastics or very soft wood, they can dig in too much and damage the surface if you really crank down on them. So, you gotta use your head a bit and get a feel for it.

So yeah, that’s my take on split washers from actually using them. Not some miracle cure for every loose bolt in the universe, but definitely a handy little fella to have in your toolbox and know when and how to use. They’ve saved me a few headaches and some re-work, that’s for sure.