Okay folks, let me walk you through my little adventure figuring out this Watts linkage thing. Because honestly, I didn’t have a clue what it was either until recently.

The “What Even Is That?” Phase

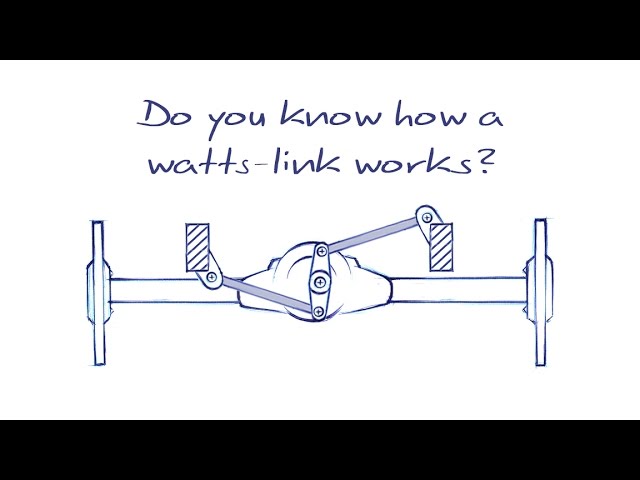

It started when I was looking at the underside of my buddy’s old classic car. He pointed at this metalwork behind the back wheels and said, “That’s the Watts linkage.” I just kinda nodded, pretending I understood. But inside? Total blank. It looked like a mess of rods and levers tucked up in there. My brain just went “Nope.”

Getting My Hands Dirty (Literally)

Curiosity got the better of me. I decided I had to understand it, not just fake it. So, I grabbed my old toolbox and headed out. I didn’t have a fancy car with one, but I managed to find a rusty old truck chassis someone was junking that had a similar setup. Step one was just staring at it. Seriously, crouched down next to it, tracing the rods with my finger.

Then, I needed to see how the bits moved together. Problem: it was attached to the axle and the car frame. Not easy to wiggle. I took some WD-40 and sprayed the heck out of all the pivot points. After a while, I could finally grab one of the long bars and push it back and forth. What happened?

- The axle moved up and down. Obvious, right? Suspension does that.

- But the sideways wobble? Almost nothing! When I wiggled other non-Watts linkages before, the whole axle would kind of shift left or right. This one? It stayed surprisingly straight up and down. It was like pushing down on a see-saw that only wants to go straight, not side-to-side.

This got me thinking. Why? I started noticing the clever arrangement:

- One horizontal bar attached solidly to the axle in the middle.

- Two vertical links connecting the ends of that horizontal bar to points higher up on the car frame.

- Another horizontal link connecting those same two higher points across the frame. This is the “Watt” part that ties it all together.

It looked kinda like a wonky sideways letter “W”. Messed with my head a bit. I tried pushing just one end of the axle. Normally, one side goes up, the other might twist or shift. But with this setup? That central horizontal bar stayed almost level, and the links forced both ends of the axle to move together, keeping it parallel. It felt restrictive, but in a really good way for keeping things straight.

The “Oh! That’s Simple!” Realization

After all that poking and prodding, the big picture finally clicked. The whole point is locking the axle in place sideways while still letting it bounce up and down smoothly.

Without it? Think of a pickup truck hitting a bump with one back wheel. That wheel goes up. The whole axle can pivot and twist slightly at the connections. This makes the other wheel tilt or push sideways a little. Not great for stability or tire grip. Feels sloppy.

With the Watts linkage? Pushing up on one wheel tries to lift that corner of the axle. But because it’s all tied together by those links connected centrally to the axle and to points spaced apart on the frame, that lifting force gets counteracted by the diagonal pulls from the links. The system forces the whole axle to go straight up or straight down, minimizing any sideways wiggle or tilt.

It’s literally just a way to physically connect points on the frame above to a point on the axle below in such a way that sideways motion becomes almost impossible, but up-down motion is easy. Less sideways dance party for the axle, more disciplined bouncing!

So, after wasting a Saturday afternoon covered in grease, staring intently at a pile of rusty metal, I can now tell you: It’s a super-smart way to make sure your rear axle stays pointing where it should, even when the road gets bumpy. It keeps the tires glued to the ground better. It’s stability control, built right into the suspension arms. Simple idea, genius execution. Now when my buddy mentions it, I don’t just nod – I can actually explain the thing!