Okay, so, carbon fiber… yeah, that stuff’s strong, right? But I learned the hard way that “strong” doesn’t mean “indestructible.” Let me tell you about the time I broke some and what I did about it.

It all started with this drone project I was super stoked about. I had this vision of a lightweight, super-fast racing drone, and carbon fiber was gonna be the star of the show. I ordered some carbon fiber sheets online, feeling all professional and ready to get to work.

First thing I did, like an idiot, was try to cut it with regular scissors. I figured, “Hey, it’s just a sheet, how hard can it be?” Let me tell you, it was HARD. The scissors slipped, the carbon fiber frayed, and I ended up with a jagged mess and a very dull pair of scissors. Lesson one: carbon fiber eats scissors for breakfast.

So, I did some research (after the fact, naturally) and learned that you need proper tools. I went out and bought a diamond cutting wheel for my Dremel. Much better! It actually cut the stuff, but… dust. Oh god, the dust. Black, nasty carbon fiber dust EVERYWHERE. I was wearing a mask, thankfully, but my workshop looked like a coal mine exploded.

Okay, cutting was (sort of) sorted. Next, I was drilling holes to mount the motors. I was being careful, using a slow speed and a sharp drill bit, but then crack. A tiny little crack appeared near one of the holes. My heart sank. I tried to ignore it, thinking maybe it wasn’t a big deal, but it kept getting bigger as I tightened the screw.

That’s when I realized I needed to reinforce the area around the holes. I grabbed some thin CA glue (super glue) and carefully wicked it into the crack. It seemed to hold, but I wasn’t convinced it was strong enough. So, I added a small patch of fiberglass cloth and epoxy around the hole. This seemed to do the trick. It wasn’t pretty, but it was functional.

Then, disaster struck again. While I was attaching the landing gear, I accidentally put too much pressure on one of the arms. I heard a sickening snap. A clean break, right near the motor mount. I wanted to cry.

This time, CA glue alone wasn’t going to cut it. This was a major break. I considered just throwing the whole thing away and starting over, but I’m stubborn like that. I decided to try and repair it with more carbon fiber. I had some scraps left over from the original sheet.

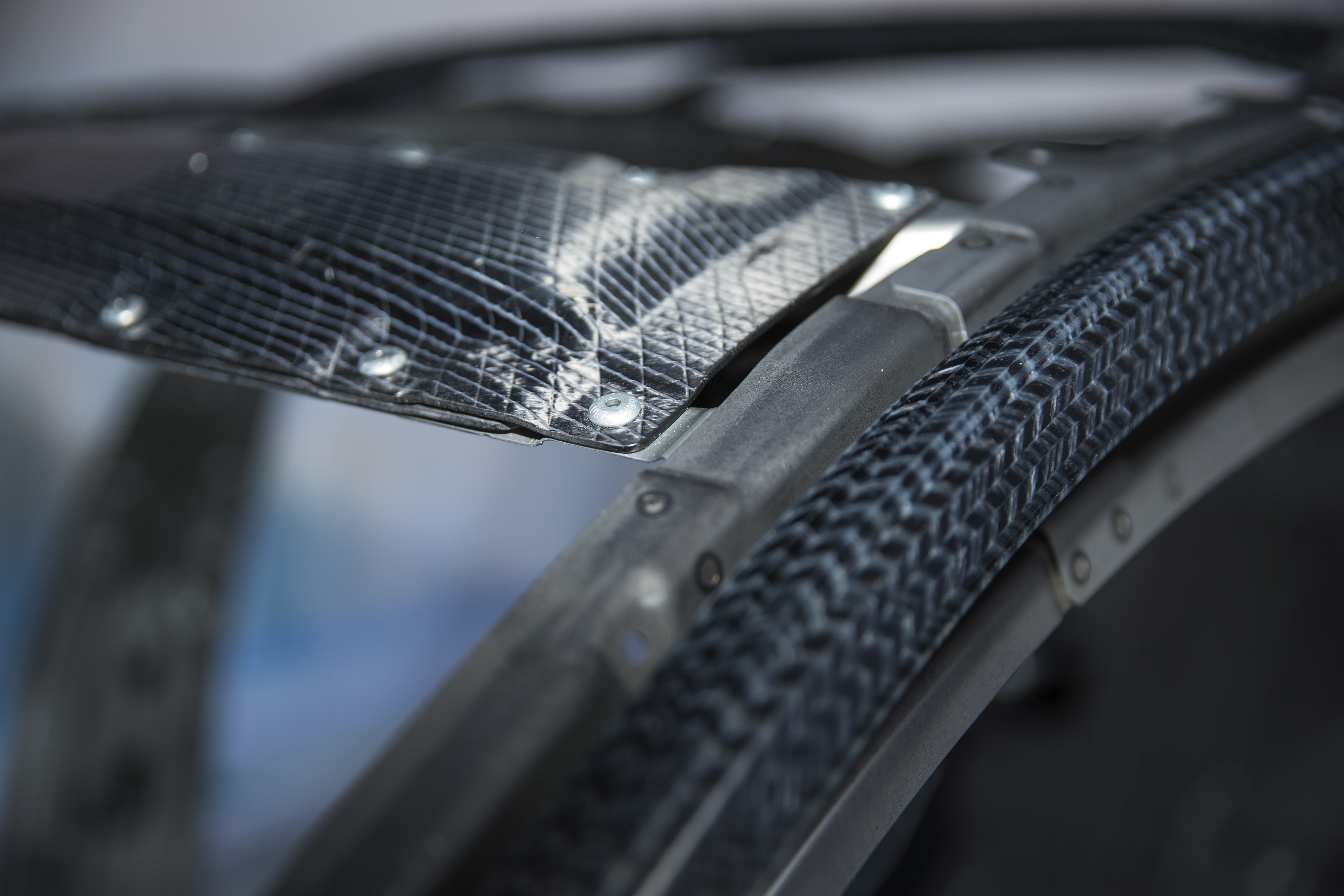

I carefully sanded down the broken edges to create a rough surface for the epoxy to grip. Then, I cut a small piece of carbon fiber to overlap the break. I mixed up some epoxy resin, carefully applied it to the broken surfaces and the carbon fiber patch, and clamped everything together. I let it cure overnight.

The next day, I removed the clamps. The repair looked… okay. It wasn’t perfect, you could definitely see the patch, but it felt solid. I reinforced the repair with a few layers of fiberglass cloth and epoxy for extra strength.

Honestly, the repaired arm was probably stronger than the original. It was heavier, though. The whole experience was a pain, but I learned a ton about working with carbon fiber.

- Lesson Learned 1: Use the right tools! A diamond cutting wheel and a Dremel are your friends.

- Lesson Learned 2: Wear a mask and work in a well-ventilated area to avoid inhaling carbon fiber dust. Seriously, that stuff is nasty.

- Lesson Learned 3: Reinforce areas around holes to prevent cracking.

- Lesson Learned 4: Epoxy and fiberglass cloth are your best friends for repairing breaks.

- Lesson Learned 5: Don’t be afraid to experiment and learn from your mistakes. Even if it means breaking a few things along the way.

Did the drone ever fly? Yeah, it did! It wasn’t as pretty as I’d envisioned, and it was a little heavier, but it flew. And honestly, the satisfaction of flying something I’d repaired myself made it all worthwhile. Would I do it again? Probably. Would I break less carbon fiber next time? Hopefully!