So, I was in my garage the other day, right? Had this idea for a new shelf, a heavy-duty one, and wanted to mount the brackets to this big metal cabinet I’ve got. The problem was, the cabinet metal is pretty thin. You know the type. Strong enough to hold stuff, but not thick enough to tap a decent thread into. And there was no way I could get a nut and bolt on the inside – just no access. I was scratching my head, almost thinking about breaking out the welder, which, let’s be honest, usually ends up looking like a pigeon had a fight with a hot glue gun. My wife still gives me that look when she remembers the “custom gate latch” incident.

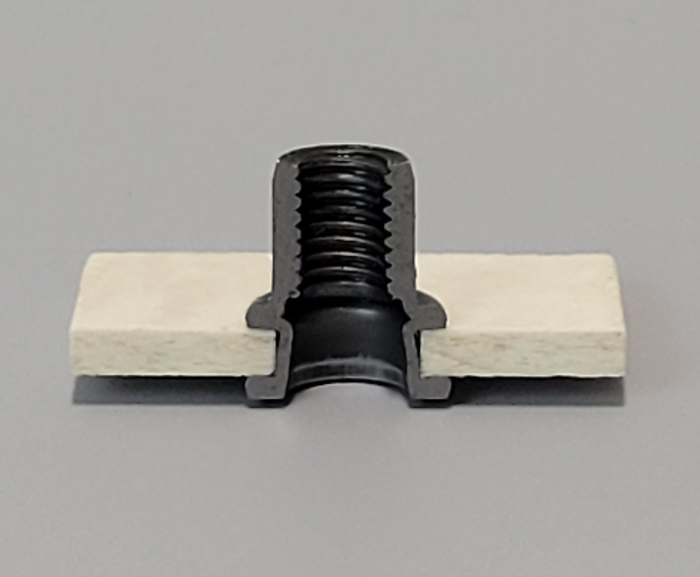

I was complaining about it to my mate down the road, and he just casually says, “Ever used rivnuts?” Rivnuts? Sounded like something you’d find in a squirrel’s secret stash. But he explained, and it clicked. It’s like a rivet, but it’s got threads inside. Genius, right?

Off I went to the hardware store, feeling a bit skeptical but hopeful. I picked up a rivnut tool kit – one of those squeezy plier-type things – and a box of assorted rivnuts. Looked simple enough, even for me.

Putting These Rivnuts to the Test

Back in the garage, I picked the spot for the first bracket. The instructions with the kit were pretty clear: drill the right size hole. And they weren’t joking. I measured twice, then drilled. Nice and clean. Took one of the rivnuts, threaded it onto the mandrel of the tool. Then I just pushed the rivnut into the hole I’d drilled. It was a snug fit, which felt good.

Then came the moment of truth. I started squeezing the handles of the rivnut tool. You can feel it working – there’s this initial give, and then it gets firm as the back of the rivnut mushrooms out and clamps onto the metal. It’s actually quite satisfying. I gave it a good, solid squeeze until the tool kind of bottomed out. Unscrewed the tool, and there it was! A perfect, strong threaded insert, flush with the metal. I grabbed a bolt, threaded it in, and it was rock solid. I mean, seriously strong. I hung off it a bit. No movement.

I got a bit carried away on the second one, I admit. Put a bit too much muscle into the squeeze and I think I slightly squashed the threads. The bolt went in, but it was tighter than it should have been. So, lesson learned: firm and steady wins the race. Don’t go all Incredible Hulk on it.

After that little learning curve, the rest were easy. Drill, insert, squeeze, done. I had all the brackets up in no time.

What I really loved about these things:

- They work brilliantly on thin material where you couldn’t tap a thread.

- You install them completely from one side – blind installation, they call it. That was the lifesaver for my cabinet.

- They leave a really neat, professional-looking finish.

- Once they’re in, they are incredibly secure.

Honestly, these rivnut things are a total game-changer for me. No more trying to weld nuts on the back of things or using those flimsy sheet metal screws that strip if you look at them too hard. I’ve already started looking around the garage for other things I can use them on. That wobbly workbench leg? Its days are numbered. If you’re doing any kind of fabrication or just need a strong thread in thin metal or tubing, you’ve got to give these a try. Way better than my previous “creative solutions,” that’s for sure. Even the wife was impressed with the shelf. Said it “actually looks like you bought it.” High praise, indeed!