Trying Out That Bolton Technique

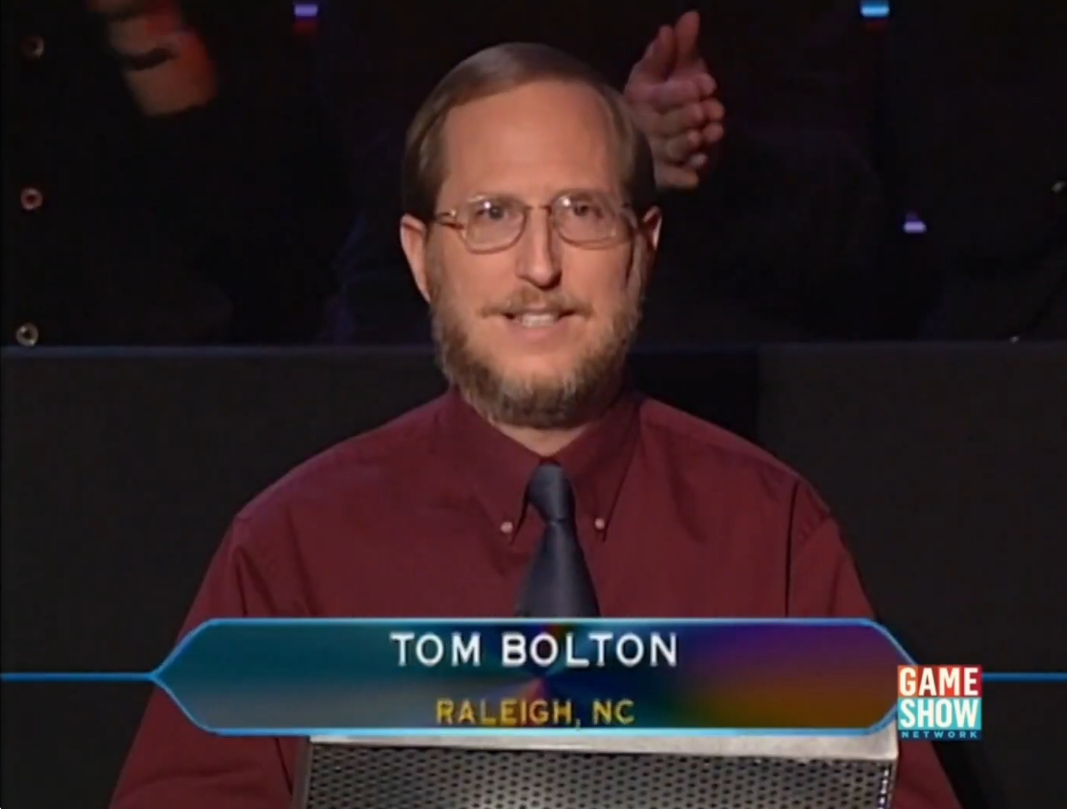

Okay, so I kept hearing about this fella, Tom Bolton. Not sure where I first saw the name, maybe some old forum thread or a dusty magazine clipping someone shared. Anyway, the talk was all about this particular way he had of joining wood. Seemed kinda different, maybe a bit tricky, but folks were saying it was strong as anything.

Decided I had to give it a go myself. You know how it is, you see something, you gotta try it with your own hands. So, I went down to the workshop.

Getting Started

First thing, had to find some decent scrap wood. Didn’t want to waste the good stuff on a first attempt, right? Found a couple of pieces of pine, pretty straight grain, seemed okay. Cleaned up the bench a bit, which, let’s be honest, needed doing anyway.

Then I gathered the tools I thought I’d need:

- My trusty old hand saw

- A couple of sharp chisels

- Marking gauge

- Mallet

- Square

Looked simple enough on paper, or at least, in my head. The idea, as I understood it, involved some angled cuts and a sort of interlocking notch. Easier said than done, usually.

The Actual Work

So, I started marking out the lines on the first piece. Measured twice, like they say. Then came the sawing. Tried to keep the lines straight, really focused. The angle was the weird part, not a standard 90 or 45. Felt a bit awkward holding the saw like that.

Then came the chiseling for the notch part. This is where things got messy. My chisels maybe weren’t as sharp as I thought. Took small bites, tapping away with the mallet. One slip and you’ve ruined it, right? Took ages. My hands started to cramp up a bit.

Did the same for the second piece, trying to mirror the cuts and notches. Lining them up was the real test. First try? Nope. Didn’t fit. One side was too tight, the other had a gap you could drive a truck through. Felt a bit stupid, honestly.

Adjustments and Finishing Up

Okay, deep breath. Went back with the chisel, shaving off tiny bits from the tight spot. Took way longer than I expected. Kept test fitting it. Shave a bit, test fit. Shave a bit, test fit. Finally, it sort of slid together. Not perfect, mind you. There was still a tiny gap, but it held. It actually felt pretty solid once it was seated.

Tapped it tight with the mallet. Stood back and looked at it. Yeah, it wasn’t beautiful. You could see the struggle marks. But functionally? It seemed to work. That weird angle lock thing did make it feel quite rigid.

Final Thoughts

So, that was my go at the “Tom Bolton” joint, or whatever you call it. Was it worth the hassle? Hmm. It’s definitely strong, I’ll give it that. But it took way more time and fiddling than a simple lap joint or something. Maybe with practice, it gets faster. Or maybe you need special jigs?

Don’t know if I’ll use it often. It was interesting to try, though. Good to stretch the old skills, even if the result isn’t exactly showroom quality. Just another day messing about with wood, I guess. Learned something, anyway. Maybe Tom Bolton knew what he was doing after all, just gotta get better at it myself.